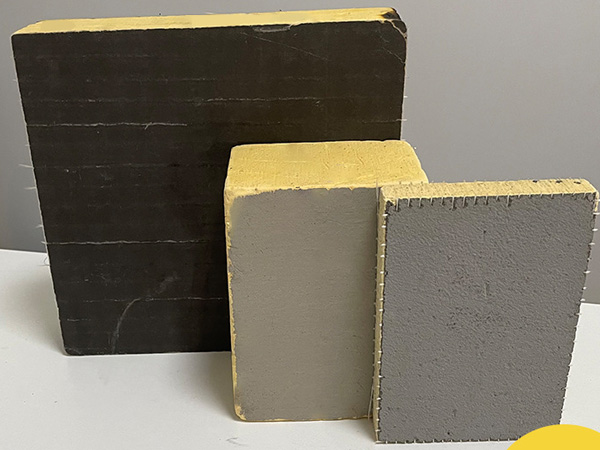

Cement Slurry Modified Composite Phenolic Foam Board

Cement Slurry Modified Composite Phenolic Foam Board represents an innovative advancement in building insulation technology. This specialized material combines the exceptional thermal properties of phenolic foam with a cement-based modified surface layer, creating a durable, fire-resistant insulation solution ideal for demanding construction applications.

Key Features

Enhanced Structural Integrity

Cement slurry modification creates a hardened surface layer

Increased impact resistance and dimensional stability

Improved load-bearing capacity compared to standard Phenolic Foam Boards

Superior Fire Performance

Achieves Class A fire rating (non-combustible)

Cement layer provides additional fire protection

Extremely low smoke emission during combustion

Optimized Thermal Efficiency

Maintains phenolic foam's low thermal conductivity (0.020-0.025 W/mK)

Effective thermal break for building envelopes

Reduces thermal bridging in construction systems

Moisture & Weather Resistance

Cement-modified surface provides excellent water resistance

Suitable for exterior applications and high-humidity environments

Resists mold growth and material degradation

Versatile Application Potential

Compatible with various construction methods

Can be directly plastered or finished

Suitable for both new construction and renovation projects

Applications

Exterior wall insulation systems (ETICS)

Basement and foundation insulation

Roof insulation systems

Fire-rated partition walls

Industrial and commercial building envelopes

Renovation of existing structures

Technical Advantages

✔ Higher compressive strength than standard Phenolic Foam Boards

✔ Improved adhesion for rendering and finishing

✔ Better resistance to mechanical damage during installation

✔ Maintains excellent thermal performance despite cement modification

Installation Considerations

Can be installed using standard mechanical fasteners

Compatible with most construction adhesives

Requires proper joint treatment for continuous insulation

Surface may require light preparation before finishing

Follow manufacturer's guidelines for optimal performance

Conclusion

Cement Slurry Modified Composite Phenolic Foam Board bridges the gap between high-performance insulation and structural durability. This innovative material offers architects and builders a superior solution for projects requiring exceptional thermal performance combined with enhanced mechanical properties and fire safety. Its unique composition makes it particularly valuable for exterior applications and situations where additional surface durability is required.

For project-specific recommendations and performance data, consult the manufacturer's technical specifications and local building code requirements.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05