Cleanroom Panel Phenolic Core

Cleanroom panel phenolic core is a high-performance, non-particulating insulation material specifically engineered for controlled environments requiring stringent hygiene standards. Combining the superior properties of thermoset phenolic foam with composite facings, this panel delivers exceptional cleanliness, fire resistance, and thermal stability for critical applications in pharmaceutical, biotech, electronics, and healthcare facilities.

Key Features

Ultra-Clean & Non-Particulating

Smooth, sealed surface minimizes particle shedding (meets ISO Class 1-5 cleanroom standards).

Resistant to microbial growth and chemical disinfectants.

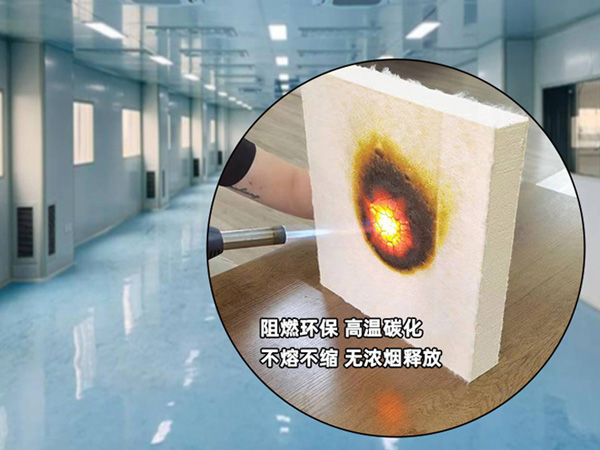

Fire-Safe Performance

Achieves Class A fire rating (ASTM E84/UL 723) with low smoke and toxicity.

Self-extinguishing properties enhance facility safety.

Thermal & Moisture Stability

Low thermal conductivity (λ ≤0.022 W/m·K) maintains consistent temperatures.

Closed-cell structure prevents moisture absorption (<1% water uptake).

Lightweight & Structural

High compressive strength (≥150 kPa) supports cleanroom infrastructure.

30-50% lighter than traditional metal/honeycomb cores.

Chemical Resistance

Withstands alcohols, mild acids/alkalis, and common sterilization agents.

Modular Installation

Prefabricated panels with tongue-and-groove edges for airtight assembly.

Compatible with aluminum/PVC edge profiles.

Applications

Walls/ceilings in pharmaceutical cleanrooms (GMP, ISO 14644).

Electronics manufacturing (ESD-safe versions available).

Hospital ORs, labs, and sterile processing areas.

Food-grade facilities requiring hygienic surfaces.

Advantages Over Alternatives

✔ Superior cleanliness vs. fiberglass or mineral wool cores.

✔ Better fire performance than PU/PIR foams.

✔ Easier to install and maintain compared to stainless steel systems.

Conclusion

Cleanroom panel phenolic core sets a new benchmark for hygienic, fire-safe insulation in critical environments. Its combination of cleanliness, thermal efficiency, and compliance with stringent regulations makes it the optimal choice for modern controlled-environment construction.

For ESD/antistatic specifications or validation support, consult manufacturer documentation.

Note: Surface finishes (e.g., PVDF, epoxy coatings) can be customized for enhanced cleanability.

Exterior Wall Insulation Materials Comparison: Cotton vs Foam vs Board

Discover how cotton, foam, and board materials differ in performance for exterior wall insulation. Learn which insulation type delivers the best results for efficiency, durability, and installation—ideal for large projects and manufacturers with bulk prod

2025-12-14

Why Choose Thermal Insulation Cotton from China Manufacturers

Discover why Thermal insulation cotton from China manufacturers is becoming a global choice for construction, HVAC, industrial protection, and energy-saving projects. Learn about quality standards, production capabilities, cost advantages, performance ben

2025-12-11

The Future of Insulation: Innovations in Phenolic Foam Technology

Discover how next-generation Phenolic Insulation Board is reshaping the future of thermal protection. Learn about new materials, fire-safety breakthroughs, sustainability improvements, and how advanced Manufacturer / Production capabilities support high-p

2025-12-08

How to Install Sound Insulation Cotton: A Complete Step-by-Step Tutorial

Discover how to install sound insulation cotton correctly for homes, vehicles, and industrial equipment. This fully detailed guide explains preparation, tools, installation techniques, safety tips, and best practices—ideal for DIY users and buyers sourcin

2025-12-05